Space flight in transition

Space technology is the basis for functions we use and benefit from every day, such as weather forecasting and navigation...

The year 2025 is almost over - Time to thank you!

We wish all of you the best for the Festive Season and the New Year!

Within the last 21 years, SpaceTech has developed from a bold idea into a…

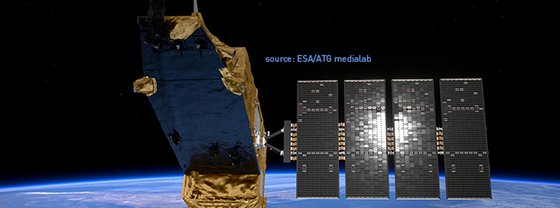

Sentinel-6B launch ahead

SpaceTech empowers second Sentinel-6 satellite with large solar arrays. Launch planned for November 17, 2025 at MEZ 6:21 a.m. with a SpaceX Falcon 9…

SpaceTech is looking forward to the Sentinel-5 launch

The first of three SpaceTech Calibration Subsystems CAS flight models for the Sentinel-5 UVNS instrument supplied will now fly on MetOP-SG-A1 and…

Successful launch of CO3D – with STI Solar Arrays

SpaceTech celebrates Solar Array number 431-438 working in orbit, launched on July 26, 2025 as part of the CO3D satellites...

Successful launch of Atomic Clock Ensemble in Space (ACES)

SpaceTech integrated and tested seven electronic units for the ground stations. We are delighted to support such a groundbreaking project with our…

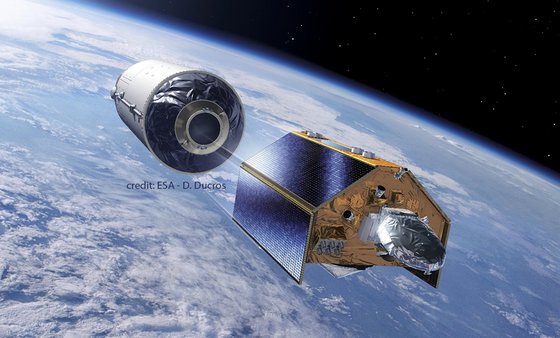

ESA’s Biomass satellite successfully launched

SpaceTech is proud, being part in the Biomass project. We were selected to design and manufacture Mechanical Ground Support Equipment (MGSE), such as…

Tag der Raumfahrt bei SpaceTech

Raumfahrt direkt hier bei Ihnen vor der Haustür...Tag der Raumfahrt bei SpaceTech in Immenstaad...

No space mission without electronics

It is everywhere and yet receives little recognition: we are talking about electronics - space electronics...